In battery cell production, production errors that are not detected or are detected too late lead to high reject rates and follow-up costs due to possible cell defects during operation. Fluctuations in electrode quality in the form of defects such as agglomerates, drying cracks, and porosity of the coating are a key source of errors, affecting load irregularities and cross-contamination.

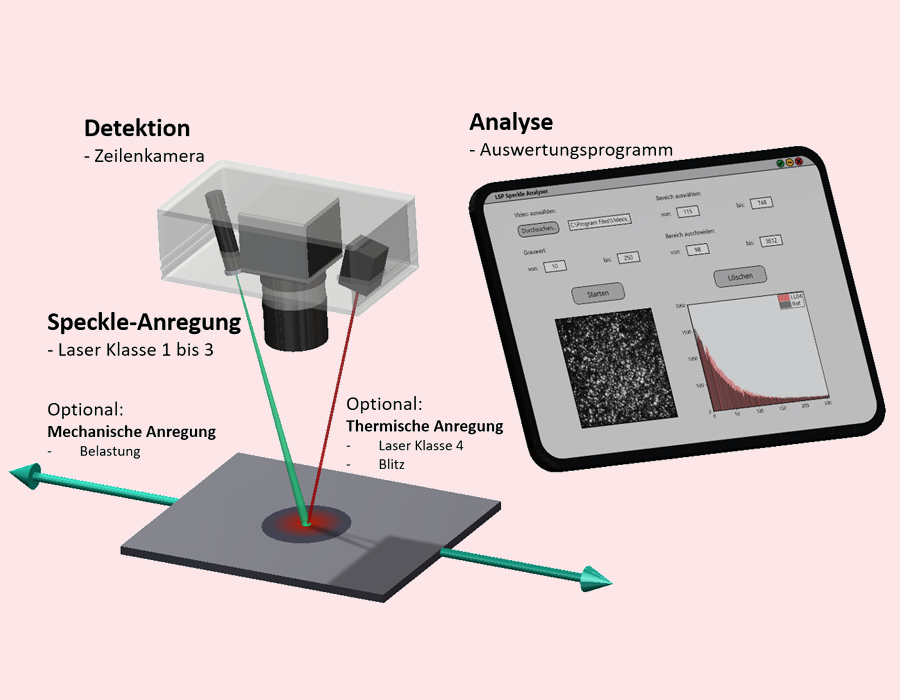

The laser speckle photometry (LSP) method developed at Fraunhofer IKTS can ensure the reliability and optimal functioning of critical battery components. With its optimized process, LSP is a simple, flexible, and yet reliable tool for quality assurance of battery components in various process stages.