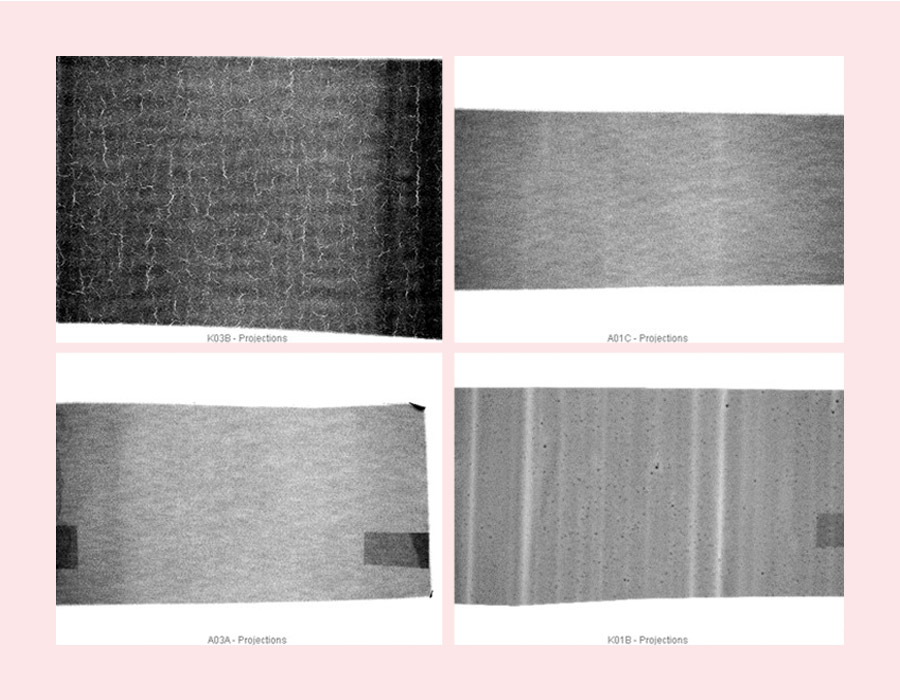

Active thermography and radiography can be used to examine flat, planar structures such as electrodes for lithium-ion batteries during production without making contact. Due to the high speed of both methods, they are ideally suited for inline testing during drying as well as before and after calendering. Both methods are currently being implemented and evaluated at Fraunhofer ZESS.

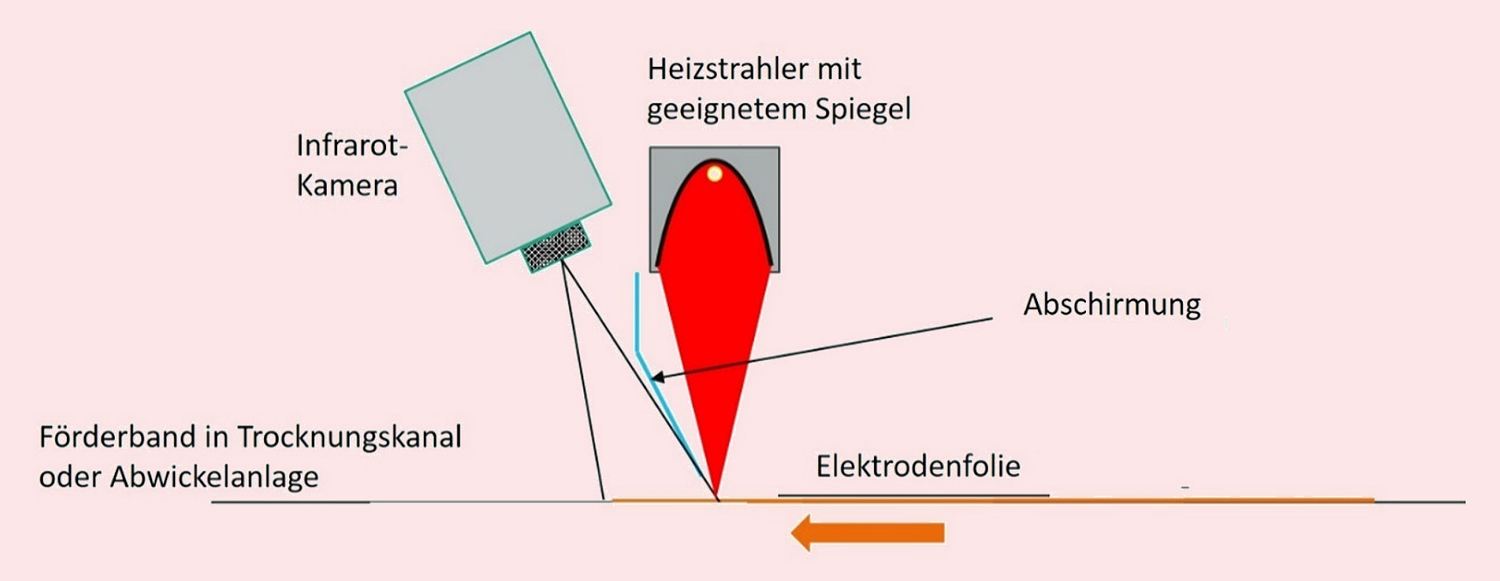

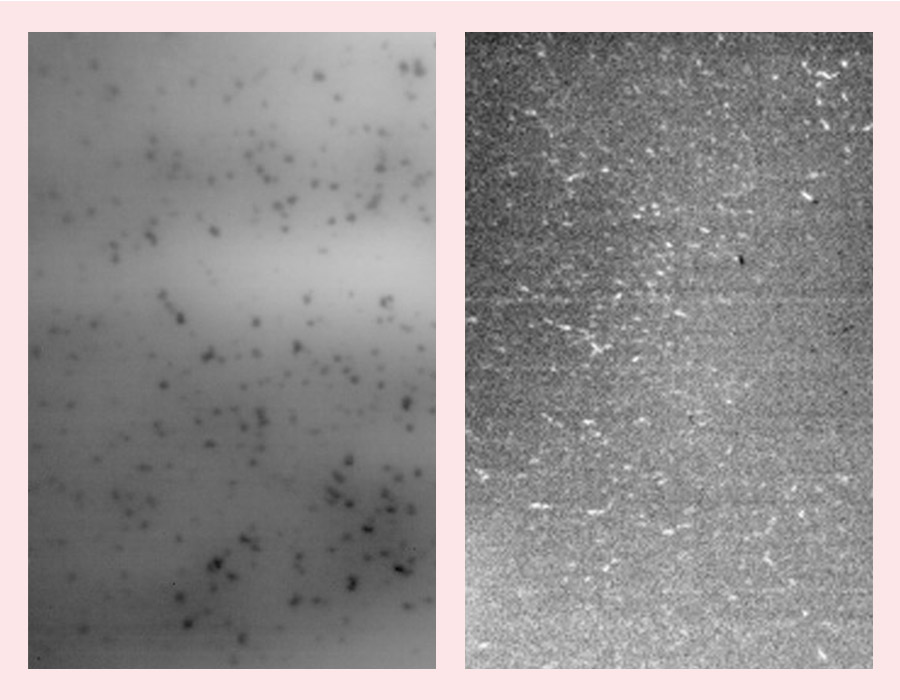

In active thermography, a small amount of heat (a few Kelvin) is applied to the electrode foil and the local heat spread is recorded using an infrared camera. All types of inhomogeneities such as pores, inclusions, agglomerates, cracks, but also density fluctuations in the electrode foil can thus be imaged and evaluated. In the drying channel, there is the alternative option of using the process heat as excitation, thus minimizing the technical effort.