Continuous mixing units, including twin-screw extruders, are of great interest in the manufacture of lithium-ion batteries. Compared to batch mixers, they can reduce process times and thus manufacturing costs. One challenge is the continuous quality monitoring of the electrode materials produced. Currently, there is hardly any suitable inline testing technology that does not influence the process control.

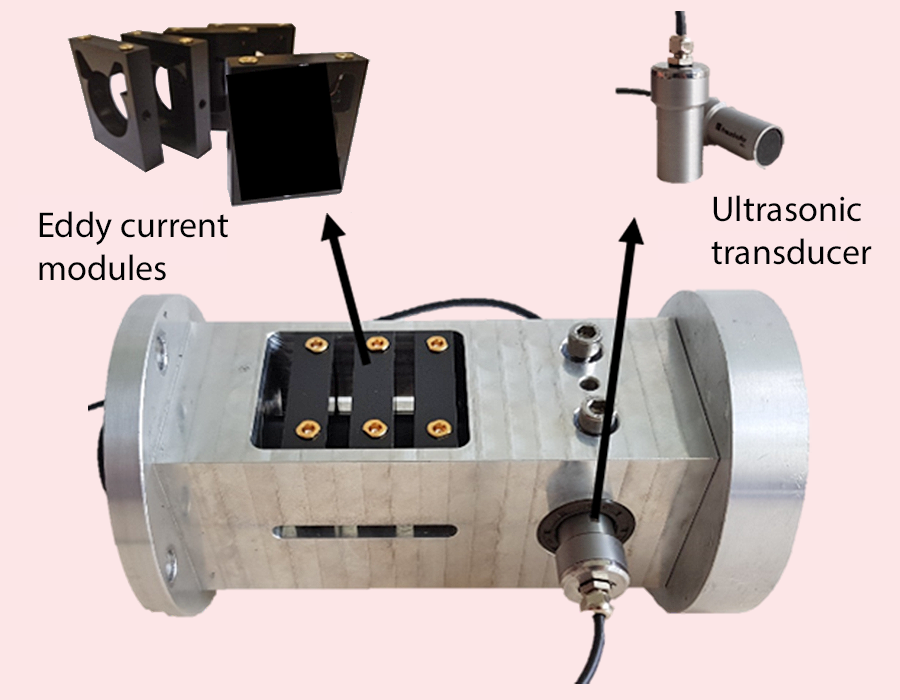

Fraunhofer ZESS is developing a multiparametric testing system that monitors the most important properties of the electrode materials and is designed for the inline monitoring of battery cell production. The testing system will be implemented in continuous processes at the outlet of the mixing unit, and the electrode material produced will be guided through a measuring section. In this area, eddy current sensors and ultrasonic transducers are installed and continuously record measurement data to evaluate the dispersion quality. The testing system can be adapted to various applications.