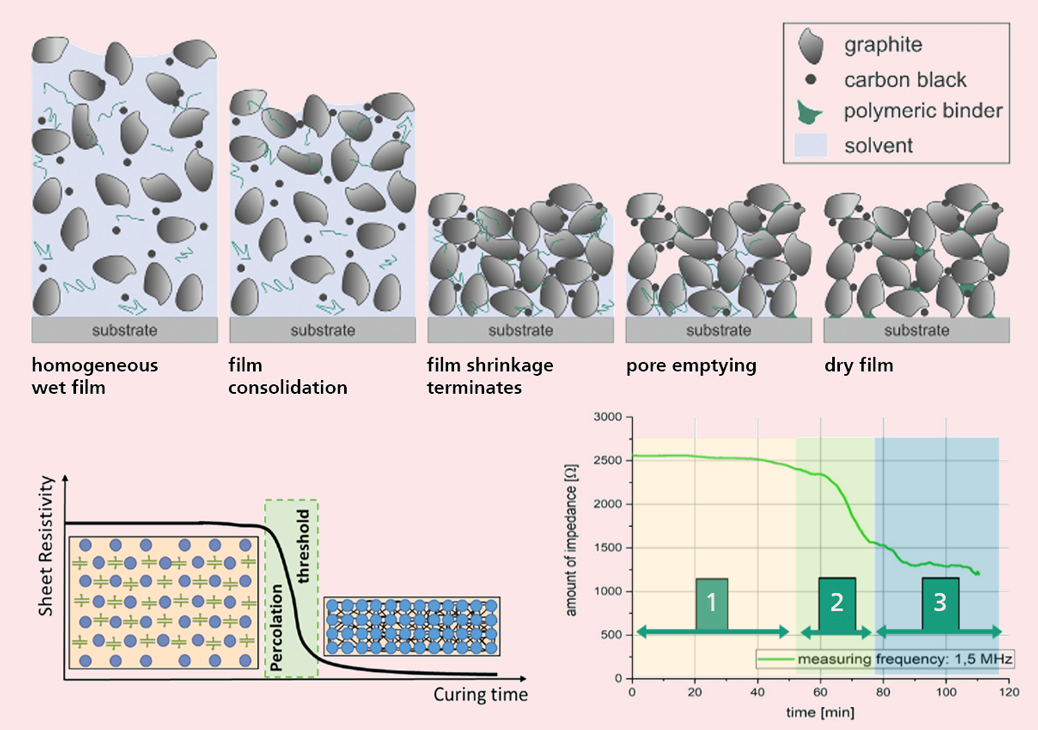

In the manufacturing process of electrodes for lithium-ion batteries, drying is a crucial factor for subsequent cell performance. This process is divided into different drying stages, to which the temperature profile in the drying channel (drying profile) should be continuously adjusted. This prevents defects such as binder migration. Since the electrical conductivity of the electrode material changes during the various drying stages, eddy current testing has been identified as a suitable method for this type of defect.

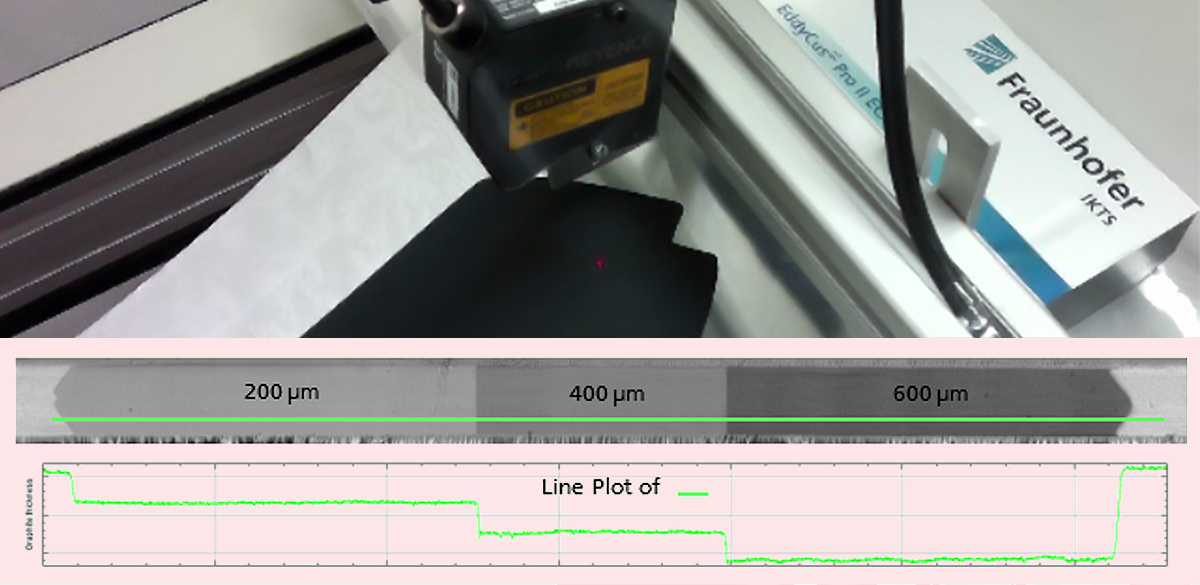

In recent years, Fraunhofer IKTS has continuously developed its eddy current-based testing systems (EddyCus® Pro-II series). These powerful and modular systems are particularly suitable for integration into the automation process of a production line. Thanks to multi-channel technology across the entire process width, they measure without contact and without damaging the material and capture integral conductivity information in real time due to the very high sampling rates.